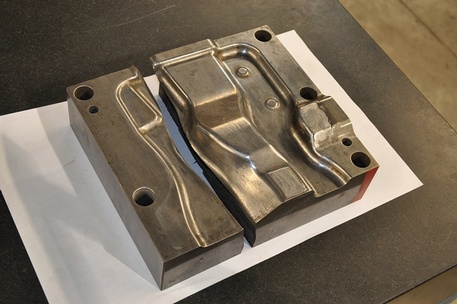

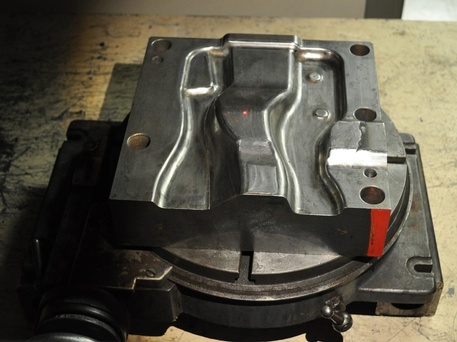

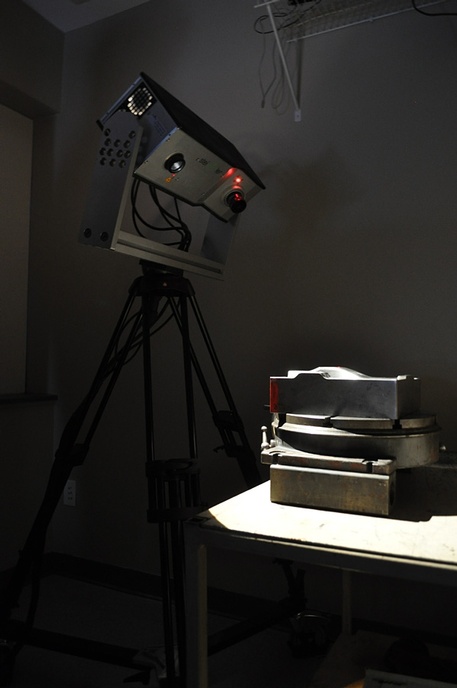

Kam uses state of the art technology using a high definition white light camera to reverse engineer any object with an accuracy of "+/- 0.001". This is an accurate way of reproducing parts where a cad model is not available or does not match the existing part. Applications include but not limited to the automotive, medical, aerospace, mining, sculpture industries. We also have full part inspection capabilities including customized quality reports.

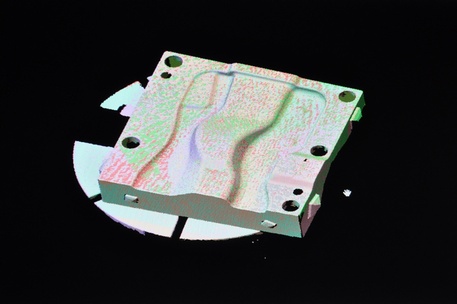

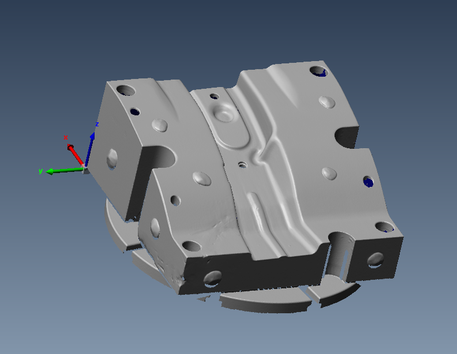

Using white light scannning technology we are able to reproduce cad data accurate with within +/- 0.001".

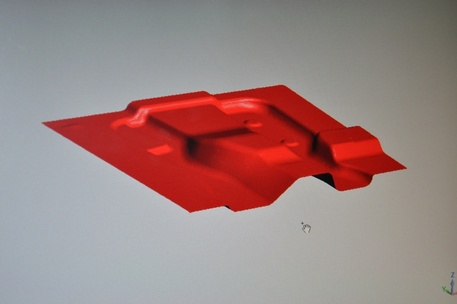

By using several different softwares we can provide you with a "ready to machine" 3d model in several different formats.

By utilizing our CNC and machining capabilities we are able to take your prototype to finished product.

Our experienced engineering team can also provide ISO 17025 certified quality inspections, colour maps, etc. using either our scanner or CMM.